Over the course of the last six months I have been exploring makerspaces as part of my continuing doctoral program at the University of Northern Colorado. Makerspaces are becoming more common in schools, libraries, businesses, and even individual homes and can be anything from a corner of a room dedicated to creative projects, a mobile cart shared by several classes, a workshop, an area in a school or public library, or a dedicated building. To make, as in the maker movement, means to exercise creativity and innovation to design, build, test, and improve projects. Makerspaces are places to create products and knowledge, not just consume them (Moorefield-Lang, 2015). Other terms used are hacker spaces, DIY (do-it-yourself) labs, fab labs, creation centers, etc. A generation ago, they were the wood, metal and sewing shops of high schools. Now they have become associated with STEM education, combining digital and physical creativity tools to promote science, technology, engineering, and practical math through hands on project-based learning (Sheridan, et. al., 2014).

Research Questions:

I began to conduct background research over the summer as part of my larger schematic on teaching creativity and innovation. As part of a course on case study research methodologies, I have designed a research project to explore the nature of makerspaces. At their heart, makerspaces should promote (and even actively teach) creativity and innovation (Halbinger, 2018), but I wanted to see how true this was in reality. Do the directors of makerspaces and the teachers who build them in their classes consciously try to use them to promote creativity and innovation in students? Do they deliberately teach entrepreneurship and other skills that future innovators will need? Because we live in an innovation economy fueled by new and creative products and services, we need to train future generations how to be innovators. But how should this be done? This question is central to what will become my dissertation research.

I have been involved with developing my own makerspaces at the last three schools I have taught at, adding pieces of equipment, supplies, materials, and projects over the last ten years. I want to know what effective practices and pedagogies are available to teach innovation through making. As I’ve built up a classroom makerspace at New Haven School, I have added capabilities, asked questions, and interviewed teachers who have already gone through the process. Many of the teachers at the Teacher Innovator Institute sponsored by the National Air and Space Museum, of which I am a part, have their own makerspaces. We received training from Josh Ajima, director of the district makerspace for Loudoun County School District in northern Virginia, who told us that makerspaces do not need to have a lot of fancy equipment. It is really all about the philosophy of making, of students using their hands to explore and learn by doing and building, not sitting and listening. It is a very constructivist approach in the best tradition of John Dewey and Seymour Papert.

Another question I have tried to answer through this project is the degree to which regular classroom teachers are making use of makerspaces and project-based learning to teach required concepts and course objectives. As a science teacher, how can I use making in a biology class to teach microbiology or paleontology or physiology? What types of skills need to be taught and scaffolding constructed that will help them be successful? Should I teach 3D modeling in a chemistry class, for example?

During background research I have identified seven different levels of makerspaces. These are:

1. Elementary schools (Rouse, Krummeck, and Uribe, 2020).

2. Middle schools (Slama, 2019).

3. High schools.

4. Colleges and universities (Wong and Partridge, 2016).

5. Community makerspaces, such as ones in public libraries (Moorefield-Lang, 2015).

6. Commercial makerspaces, set up as a for-profit business funded by patron subscription fees (Sheridan, et. al., 2014).

7. Professional in-house makerspaces, for specific research and development projects.

I wanted to know if these different levels of spaces have different types of equipment, projects done, challenges, training, and funding issues. I decided for my case study class this semester to do a comparison between these different levels and report on my findings. After gaining IRB approval and trying to work through all the COVID craziness, I contacted several makerspace directors for the levels that I lack experience with. These are middle school, commercial, and community. University level makerspaces will have to wait for another time.

Methods and Choice of Makerspace:

I needed to find makerspaces within proximity of my home in Orem, Utah and did research in the local newspapers to find any articles. I knew that our local public library has a makerspace, but it has been closed during the pandemic. I found a library-based makerspace in a middle school in central Salt Lake Valley. I found a commercial makerspace in Provo, a neighboring community. I located names of directors and contacted each makerspace, but setting up appointments was challenging during the pandemic and some of the interview dates had to slip until after Thanksgiving as COVID cases surged in Utah and the governor locked down all after-school activities. I set up a Zoom meeting with one of the Orem Library makerspace director and took tours of the middle school and commercial makerspaces. I sent a list of questions to each person in advance so that they could be ready for my visits. During the visits, I videotaped my tours and interviews, then transcribed the footage using Otter software, cleaning up the results for clarity.

Elementary School Makerspaces:

In the spring of this year I interviewed three teachers who are part of the Teacher Innovator Institute at the National Air and Space Museum and are all 5-6 grade teachers. Two have classroom makerspaces, the third is the director of a district-wide dedicated makerspace.

They told me that the complexity and purposes of makerspaces in elementary school depend greatly on the grade level of the students. Early grades generally use a “craft corner” approach – an area of the classroom with supplies for art projects including construction and drawing paper, pencils and crayons, safety scissors, cardboard boxes and tubes, glue, and so on. The types of projects used are mostly for teaching fine motor skills and general learning and literacy. Challenges included purchase and maintenance of supplies. Funding is usually achieved by donations. One teacher posts a list of needed supplies at the beginning of the school year and asks parents to send whatever they can in with their students; another teacher provides a required purchase list for each student at the beginning of the year. Supplies must be organized into two categories: those that are freely usable by students and those that can only be accessed by the teacher for particular projects . Otherwise, the needed supplies will be used up, because some students will randomly glue things together just for fun (even in high school). Critical supplies must be rationed.

By upper elementary grades the students have reached a level of sophistication sufficient to begin higher-order projects, such as learning simple computer programming (coding) with modular block languages such as Scratch. They can begin to learn 3D modeling and printing, simple electronics using snappable circuits, and engineering design projects for constructing objects such as bridges and towers. The teacher who directed a district-wide makerspace found that the greatest challenge was completing projects in the limited time each student had to use her space, since they could only reserve it for 1-2 days per month across multiple schools and classes.

As the sophistication of projects increases, so does the need for more complex equipment. Usually this is in the form of kits or self-contained programmable robots such as LEGO Mindstorms, Cubelets, Spheros, and Ozobots. Some time must be spent teaching students the basics of each type of technology; to solve this problem, many teachers have experienced students pair up and teach the less experienced. This fosters a culture of cooperation and motivates learning.

For my central question about creativity, the three elementary teachers agreed that creativity and innovation are essential skills and should be taught early to students. As Michelle, a fifth grade science teacher, puts it:

“I have a makerspace in my classroom this year, and they’re all the time in my makerspace creating weird things or beautiful things or whatever, but they love to make things and make new things out of old things. And they go, like, you may have assigned everybody the same STEM project, but they carry theirs a little bit farther than what you’ve even thought about it going.“

She deliberately teaches them to be aware of their creative process by reflecting on the experience afterward through a FlipGrid video:

“I always make them do a FlipGrid after where they talk about, you know, what they used, what their idea was and why they wanted to build that. And it really encouraged the other ones to take it a little farther than what they were, instead of just making a flower out of a pipe cleaner. They were actually making things.“

Michelle recognizes the importance of creativity for scientists and why it is an essential part of science instruction:

“Because my husband’s a scientist and my daughters are scientists, I know that they have to think creatively, and they have to think outside the box. And they have, of course, real-world problems that come with their jobs, but they have to come up with ideas that haven’t been thought of before. And they have to be creative in their approaches.“

She does not deliberately teach how to be creative through any lesson plans or curriculum, but she encourages creativity in many ways, such as allowing students to go beyond the requirements of the project, experiment, and then reflect upon it. She also encourages creativity by putting constraints or limitations on their projects, such as a budget and the need for having a plan worked out before any materials are handed out:

“There’s one STEM project that I do that they have the materials and all the materials cost money. Well, the tape, charge them per centimeter because I don’t want them using all my tape. But it’s so funny, I’ll put this stuff out that I think has nothing to do with a project and they will find a way to use it. You know, so I just try to provide as many materials and they always have to make a plan and they have to list materials. And you know, that’s a hard lesson for some of them because they have to agree on a plan within their group.“

This process teaches cooperation, collaboration, communication, and problem-solving skills in addition to creativity and innovation.

She finds that there is never enough time or space, as creative makerspace projects always take more time and room than anticipated. She does not get any funds from her district specifically for her makerspace and has to use her allotment of instructional money to support her makerspace while relying on parents to donate what they can.

Middle School Makerspaces:

I chose to profile the makerspace at a middle school in the central part of Salt Lake Valley. The neighborhood was first built in the 1950s and 60s during the Baby Boom and is now beginning to age. Some of the older homes have been provided for families of refugees from western Africa and middle Eastern countries, whose children now attend the school. There is also a large homeless shelter whose children attend the school. To balance this, students from a gifted program in the district also attend this middle school. There are about 1100 students in the school under normal conditions, but only 650 of them are now attending in person with the rest online during the pandemic. 62% of the school consists of minority students, mostly Latinx, and 38% white. 24 flags are represented in the school’s library, and it is common to hear west African dialects and Arabic spoken in the halls.

The makerspace has been established in the school’s library, and the librarian began the space when she first started at the school 1 ½ years ago. She inherited an unused library budget and decided to create a makerspace with sets of programmable robots including Spheros, Ozobots, and Cubelets. She purchases 20 iPads to control the robots and a set of Keva blocks for general engineering design projects. She has also purchases a 3D printer but has not yet used it.

She finds the Keva bricks to be in great demand, as they are simple, unbreakable, and can be used to build many structures. While I was observing, the makerspace was open for an after school club. She had the students create cantilevered bridges across gaps between tables, or at least create the longest overhang of bricks. Without mentioned terms like torque, center of mass, or even cantilever, she was teaching engineering principles. There were 13 students there, seven girls and six boys. The girls sat with other girls and the boys worked with boys. The director told me that this is often the case at the start of the year but eventually the girls and boys mix together across genders. This was only the third time they had been together because of multiple closures due to the pandemic. Of the students, four were black and the rest white; two of the boys working together were speaking an African dialect to each other. All were showing persistence and creativity in their approaches to solving the problem; when their bridges collapsed, they quickly picked up the pieces and started over. It was a safe place for them, without criticism.

She will move them on to the Spheros, creating challenges for the students to build the tallest towers they can with the Keva bricks, then use the Spheros to attempt to knock over each other’s towers and protect their own. Eventually, the Spheros are used to push a small soccer ball around, with larger programmable robots used as goalies. Teams attempt to play soccer while controlling the robots with their iPads. She doesn’t provide much instruction but relies on the experienced students to teach the newbies and knows that the students, if given a fun challenge, will figure it out for themselves.

Her most important goal for the makerspace is not to teach science, engineering, or creativity per se but to provide a safe place for experimentation. If that exists, then creativity will be a natural result. She attends to the social-emotional well-being of the students, knowing that many of them come from challenging home environments.

There are challenges. She has had sufficient funds so far, but her equipment is new enough that it has not broken down yet or needed replacing. The Keva bricks are so basic that they will last many years; she simply needs more of them. Her biggest challenge is having enough time with students; it is an after-school club that meets only once per week for one hour, but this year the school has received a grant for a program that lasts 30 minutes each day, cutting into the short amount of time she has with the students. She can only do one simple challenge in the 30 minutes left. To help solve this, the lab and materials are available during lunch. As the year progresses and students learn more, she expects more students to come during lunch. The pandemic has limited how far she has been able to teach this year. She has largely come up with her own projects and challenges, with help from lesson plans created by the makers of the robot kits and Keva bricks. It is the lack of time needed to train herself that has prevented her from using the 3D printer.

She sees her makerspace as a space for creativity. As she puts it:

“Makerspace is for an individual to come in and create and have ownership, something that they’re able to do on their own [and to] build and collaborate with others.”

As to whether classroom teachers use the makerspace to support their classroom content, she says that some are beginning to do so. For example:

“One of our teachers teaches Greek mythology and that history part and so she gets into the catapult. And so I ordered through Keva planks, catapult building . . . they’re able to take the Keva planks, and all of that and build the catapult set they’ve been learning about on that. Also, with the Keva planks, you can build the castles, the bridges, all of those kind of things that they had back in that era, for those students to be able to compare and to understand more how all those things were built.“

She believes that makerspaces can be models of inclusion as students learn to collaborate and work with each other. She has the more experienced students work with beginners with activities that are fun, safe, and cooperative. One example is to use the Keva planks to build towers, which teaches architecture and engineering, then use the Sphero robots to attempt to knock down each other’s towers. The teams use some Spheros to guard their own towers while attempting to attack the others. She emphasizes teamwork and emotional learning:

“. . . it was just awesome to watch them talking and working with each other on that. And that’s what I would see is kids getting along, and just trying to create and build something together. They weren’t making fun of other’s buildings, everybody worked great with each other. And I think that is what I want to see. I want to be able to see that kind of stuff because they don’t get that in the classrooms.”

Her makerspace isn’t about coding or learning math or STEM. It is about providing social-emotional learning and being able to have fun and work together with students from diverse backgrounds. As she explains the main goal of her makerspace:

“Mine isn’t about them coming away knowing coding, or them coming away being better math students. My goal is for them to come away with a social emotional learning. . . . my master’s studies has been in SEL, and that’s what I believe makerspace does is it helps students get that, that social emotional learning, especially when they’re working with others, . . . really, they’re playing with others. And they’re playing with others that are so different. They come, all of them come from so many different backgrounds. And what a great thing to see, I think, and to see them get along with each other, talking and working with each other. When they were building the city there, it was just fun to watch them talking with each other. And, you know, and just getting along.”

This was a finding that surprised me – that a makerspace was more than a place to learn about STEM fields. It has a higher purpose to teach students collaboration, creativity, communication, and to foster inclusion of all students.

High School Makerspaces:

I did not visit any high school makerspaces, partly due to the COVID pandemic and partly because I already have considerable experience with this level. I have helped to build makerspaces at several high schools, including my current school.

New Haven School

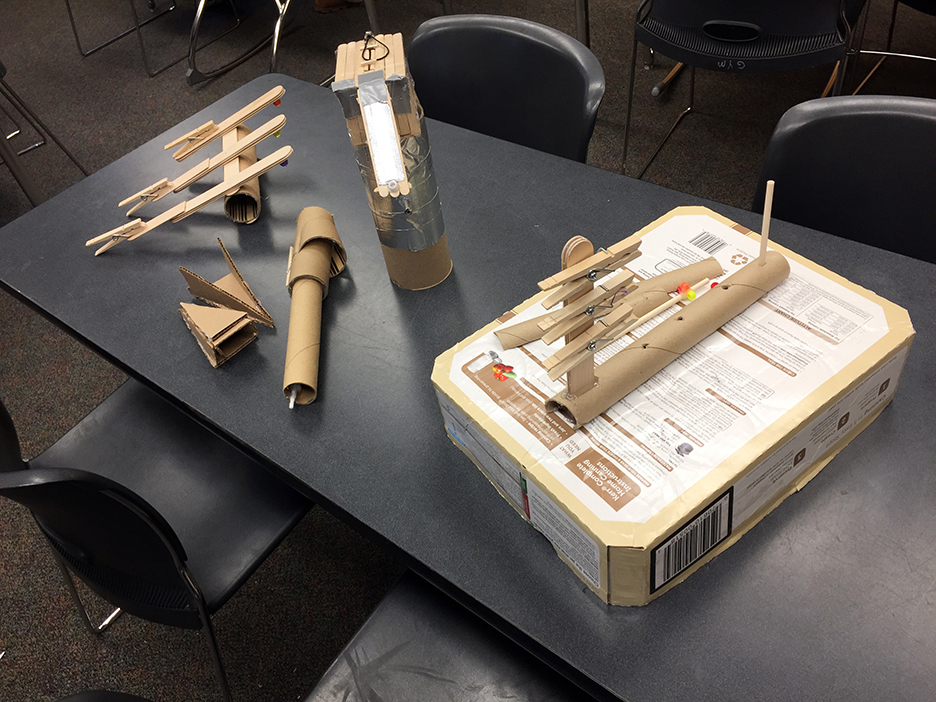

Using my school classroom budget and a grant from the National Air and Space Museum, I am building a makerspace in the corner of my science classroom. This space is used to support my classroom activities and projects, which are all centered around content objectives. For example, I have cardboard boxes, foamcore sheets, hot glue guns and glue, string, straws, and beads which are used for making working models of human hands for our biology unit on the musculo-skeletal system and 3D models of the nearby stars for astronomy. I purchased a 3D printer and teach my students how to use TinkerCad and SculptGL to create models that we can print out, such as models of viruses for our microbiology unit, or dinosaurs for a unit on paleontology, or organic molecules for chemistry, or terrains on Mars for astronomy (as explained here: https://spacedoutclassroom.com/2020/08/21/3d-printing-mars-terrains-using-mola-data/ ). We use PVC to build frames for stop-motion animations and physics equipment; wooden dowels, popsicle sticks and clothespins for rubber band shooters in physics; and Scratch software to design review games and animations.

I feel that a makerspace is not just equipment and supplies but also software, and that media design skills are a necessary part of the process. I use a mastery system of grading based on my own model of how to move students from passive to active to creative projects. Each unit, I list the concepts that need to be mastered on the vertical scale of a matrix and ways that students can demonstrate mastery across the top. They are encouraged to move along a continuum from passive to creative, and creativity is one of the characteristics that are graded during their peers’ Critique process, which provides positive suggestions and feedback so that students can improve their projects. All of the projects are graded on a scale of 0 to 8, with zero being no demonstration of mastery yet and 8 being full mastery with high creativity, quality, and with teaching concepts to others. I have submitted an article about this process to Educational Leadership and will write about it in more detail in a future blog post.

The result of this process has been an increase in both creativity and concept mastery. Students are now more self-directed and will read the textbook or search the Internet to find the information they need to create their projects; I rarely need to lecture any more. My philosophy is that we need to invert Bloom’s taxonomy and put creativity first. Imagine that creativity is an apple seed, growing down to the roots of knowing facts, understanding, applying, analyzing, and synthesizing and growing up to innovation.

Other High School Makerspaces:

Other schools have various types of makerspaces. In some, dedicated rooms or spaces are built that house a variety of tools and support many student and teacher led projects. They are often created as part of Career and Technical Education courses, and Utah has a robust CTE program and a series of magnet schools called U-Tech where high school students can attend from their local schools for three hour classes each day in such fields as Medical Assistant, Dental Assistant, Welding, Computer Networking, and Media Design. I ran a media design program at what is now known as M-Tech (Mountainland Technical College) for nine years, teaching adult education and high school classes.

Other schools have initiated national programs that teach entrepreneurship and engineering. At least two Utah schools are part of Project Lead the Way (PLTW), a turnkey solution that includes curriculum, projects, and certifications geared towards engineering design. It is rather expensive, at a $50,000 annual subscription fee. Another national network that is part of at least three school districts in Utah is the Center for Advanced Professional Studies, where students learn entrepreneurship by working with local businesses to design and test solutions to problems and market their results.

University Makerspaces:

I have yet to visit a university makerspace, but through my research I can see that there are several types. Some colleges have makerspaces inside their school libraries open to students for working on projects on a pay-for-materials basis. In some cases, community members can also use the makerspaces for a fee. Some colleges of education create makerspaces as part of their teacher preparation programs to train prospective pre-service teachers how to use and run makerspaces.

University engineering and design programs usually have the most complex makerspaces. They hope to entice the best students to enroll at their schools and to promote entrepreneurship and new start-up businesses that will enhance local economies and bring in more community donations. They act as incubators and kickstarters, sometimes even providing grant money to promising student teams. At Brigham Young University, the Venture Lab supports engineering and design students by promoting their business ideas through an Ideathon, where students can pitch an idea and receive feedback from the audience and local business leaders. Small start-up grants support materials costs, and the lab provides construction and testing equipment for a wide variety of projects ranging from electronics to wood to metal to plastic fabrication, with commercial level additive and resin 3D printers, milling machines, CNC routers, laser cutters, etc.

At Lassonde Studios at the University of Utah, an entire new building has been built as both a dormitory and makerspace for students who are entrepreneurs, creators, programmers, designers, and innovators. The entire central core includes fabrication shops and meeting spaces that can be used for free by residents of the hall for design, prototyping, testing, and marketing ideas. At $45 million, the building is a hub for entrepreneurship and is rated as one of the ten best university makerspaces in the world. You can check out a video of student entrepreneurs at Lassonde Studios here: https://youtu.be/9C0DXJjiAi4.

I do not know how the pandemic has impacted these spaces. I hope to visit one or both of them during winter break or early next year to complete my initial research into makerspaces.

Community Makerspaces: Orem Public Library:

The Orem Public Library in Orem, Utah established a makerspace four years ago. It is currently closed because of the pandemic, but equipment can be checked out by community members. I interviewed one of the directors of the space concerning its purposes and goals, challenges and successes.

As more libraries began to have makerspaces, library patrons began to ask if the Orem library would be building one. As he put it:

“Our division manager had seen them at other libraries and thought that it would be a really cool service for us to offer. We have had patrons in the past asking if we were going to have something like that, that they’d seen around or if we were ever even just going to have more equipment to check out, like projectors, and digitizers. The kind of archiving and family history aspect of it is really big in the community. So people were asking for those type of things.“

The library staff looked at community interest and the types of needs and services they could provide. They could see that family history and archiving was a common request, including digitizing old photographs and videos, supplying high end Bernina sewing machines, providing 3D printing services, and creating a video and sound editing booth with green screen, lights, cameras, music keyboards, and computer software. A conference room in the library was tasked with becoming the new makerspace and a community grant of $11,000 was used to purchase equipment. The new director traveled to other communities and to a commercial makerspace in Washington, DC to learn how makerspaces were working.

After four years, they have seen some interesting patterns develop in how the space is being used. As he explains:

“I think the archiving is a big one, being able to digitize your slides and negatives, and actual like print photos, and your VHS tapes and other cassette tapes. The kids who are getting into 3D printing has probably been the most popular. It’s been really popular with kids who are kind of interested in that or learning about that or just interested in the technology. And then also community members who are developing prototypes and or replacing like little things around the house that they’ve had for 40 years but never got rid of because they love it, but they’re missing this one little piece, and then we can usually help them print that. But other than that, I’d say converting stuff to digital has been the number two interest in there. And then we’ve also had a lot of people interested in, like the sound booth, and the green screen wanting to create some blogs and vlogs, creating content.”

He went on to say that the most common thing children want to print is a toy off of Thingiverse for $1 or so in plastic. The sewing machine can do simple embroidery and is used for costume design. They hold occasional cosplay classes to support this demand in the community.

The major challenges of the library makerspace is that of sustainability. As the 3D printers are used, new ones must be purchased to replace them as they wear out. Other equipment is more durable but expensive and there is only a limited amount of operational budget. Space is at a premium, with the green screen, lights, and other equipment crammed in his office as the library builds a new auditorium and additional conference room spaces. A final challenge is training; his major was film and sound editing, and he has an assistant who has learned how to do 3D modeling, but they have little time to teach patrons how to use the higher end software or machines they have less experience with. They have to assume patrons know the software already and can only occasionally provide one-on-one instruction when the makerspace is not very busy. Most of the adults who want to digitize their archival photos do not know how to do this. I asked if they have a need for volunteers to help teach patrons and he enthusiastically agreed and said he is hoping to set up a volunteer schedule when the makerspace reopens. I volunteered to help out when that time comes; it will give me a chance to see the makerspace in action and get a better feel for the types of projects and patrons there. They have created a few training videos but more are needed, and he has insufficient time to film and edit them.

To learn more about the Orem Library makerspace you can take a virtual tour here: https://youtu.be/pnmJgHbro3o.

Commercial Fee-based Makerspace: ProLab Studio, Provo, Utah:

To understand the commercial level of makerspace, I researched labs in my community and found a relatively new makerspace in downtown Provo, Utah. There had been one previously in the same neighborhood but when I tried to stop by and see it a year ago it was no longer in business. When I contacted them the new space, one of the employees was willing to answer the questions that I sent him and act as my tour guide when I visited on Friday last week.

This is a makerspace created as a for-profit business venture. It had originally been set up by the owners for a different purpose and they had bought the machines and equipment solely for doing custom work. When that did not pay off, they decided to open up the shop as a makerspace in the community for anyone to pay a monthly subscription fee and come in to use the equipment themselves.

They have a variety of machines and tools at a higher level than a community makerspace, including an embroidery machine, a dye-sublimation large-format printer, four well-used 3D additive printers including two Prusas, two laser engravers, a CNC router, a milling machine, three resin-based 3D printers, and a variety of electric tools such as table saws, band saws, drill presses, etc. The wood tools were in a separate area with a vacuum system to control sawdust and doors to drown out some of the noise.

They do not make enough money off of the subscriptions themselves to pay for employees and make a profit, so they also accept custom jobs online from people that need projects done but who don’t what to do them themselves. They rent out part of their floor space to other companies: a sound booth for recording podcasts, a company that makes custom Nerf guns (there were many boxes of Nerf bullets in the back storage area), and a design studio. They inherited a large space in the basement repair garage of an old car dealership in the business district of southern Provo. The dealership is so old that among the signs painted on the bricks on the outside of the building is one for Edsel cars. The basement repair shop area has been cleaned out, partitions knocked down, and is now rented out entirely by ProLabs. They are only using half the space so far, and have plans to expand their woodshop into the large storage area in the back.

They had their best month ever in March of this year and then the coronavirus hit, slowing things down. It was fairly quiet when I was there – no patrons were using the equipment and only a few laser engraving projects were being done. The upstairs portion of the dealership was opened up as a display area and was housing a Christmas boutique, so quite a few people were walking around the area and eating filled churros from a food truck parked by the dealership, but none were finding their way around the side and down to the makerspace.

The types of projects done range from hobby crafts, learning new skills, and personal projects through prototypes of products for businesses to small-scale manufacturing. Some patrons see a product in a store that they feel can be made cheaper, or a business might want a set of embroidered caps or color-printed shirts for a promotion or a corporate event or team. Some patrons come to gain experience and practice different making techniques to enhance their resumes or job prospects. Looking in the trash bin, there were quite a few thin plywood sheets that had been cut out into patterns of Christmas tree ornaments; apparently many of the personal projects this time of year involve making DIY Christmas decorations, including wood cutouts for tole painting. One sheet had a girl’s name cut out of it, possibly as a birthday or Christmas gift that will be a decoration in a daughter’s room.

My tour guide told me that the major challenge had been having enough patrons lately due to the pandemic. They have plenty of space, a rarity for makerspaces, and their equipment was already paid for by the previous business. They use subscriptions for rental, employee salaries, and purchasing new or replacing old equipment. They have not done much in the way of advertising, as word-of-mouth has been sufficient up until now. The type of people who want to use makerspaces are generally good at searching them out using Google. They have weathered the COVID slowdown by increasing their custom work orders, which is really their major source of income.

The largest challenge they have is training. They cannot do much training of patrons; although some of these machines are fairly easy to use, such as the laser printers, other equipment such as the wood lathes and milling machines takes quite a lot of training to use safely. Employees do not have the time of training themselves to be able to teach others how to use the equipment, so they must rely on people already having expertise. They know most of their patrons and their capabilities well and so far haven’t had to set up any type of database or certification requirements, but they admit it may need to be done. They have not yet held any in-house classes but have created a video for training on one of the machines and may decide to do more. There will still need to be a hands-on component to the training; not all the knowledge needed to effectively run a complex machine can be learned from watching a video only.

Professional In-House Makerspace: The Jet Propulsion Laboratory:

The Jet Propulsion Laboratory (JPL) in Pasadena, CA is one of ten NASA field centers. It specializes in designing, building, and testing robotic space probes that explore Earth and other planets. To accomplish this mission requires highly sophisticated knowledge of interactive design, electronics, mechanics, propulsion, communications, data processing, and other engineering and technical skills in addition to expertise in planetary science and orbital mechanics.

Space Probe Approval

For a space probe to be approved and developed takes a number of steps. First, Congress must approve funding for the probe based on opportunities for launch, which depend on the orbits of the planets. For example, probes can only go to Mars once every 26 months when Mars and Earth align. An Announcement of Opportunity is made at the annual Lunar and Planetary Science Conference in Houston, and teams of scientists at various universities and space research centers compete to have their instrument fly on the probe. They submit proposals and the best ones are given seed money to create and test a prototype. The designs which test out the best and fit with the probe’s mission are selected and the scientific groups then build a final version which is shipped to JPL. Meanwhile, the bus (basic structure of the probe) is designed along with its systems, which include propulsion, communication, power, navigation, and landing sub-systems, if needed. Prior to the development of design software, space probes took up to ten years to design, build, and launch because each department designed its own part of the probe, then had to redesign when their parts didn’t fit with the other parts.

The Project Development Process

In the early 2000s, the Project Design Center was created to speed up the process of probe development as all system engineers work in the same room interactively. If propulsion requires larger fuel tanks, then communication and power systems need to be moved. All parts must be under an established weight and be able to fold together to fit inside the faring of the launch vehicle. The probes are a real-world transformer: They fold together for launch, then unfold for their cruise to another planet, then transform again for aerobraking or retro-rocket orbital insertion, then fold another way for entry, descent, and landing. Once the design is approved, the major parts are machined in the Fabrication Shop, which houses five 5-axle milling machines, a specialized 25-foot drilling tower, etc. Small devices and their micro-electronics are built in the Micro Devices Lab. All the parts are assembled and tested in the Assembly Building, which has a series of clean rooms. Once the vehicle is built and working, it is disassembled and shipped to the top of the hill and the parts are subjected to environmental stresses in the Environmental Test Lab, generally referred to as Shake and Bake. Parts are placed on shaker tables to simulate the vibrations of launch, placed in an acoustic chamber and blasted with over 150 decibels of sound to simulate the acoustic stresses, and placed in vacuum chambers under intense radiation to simulate the vacuum and radiation environment of space. Many parts fail; for most components of a probe, several copies must be made so that at least two space-worthy versions are available, the primary and backup. Once testing is complete, the parts are shipped to Cape Canaveral where they are reassembled inside the launch faring at the top of the rocket inside a clean room. Finally, they launch, cruise to their destination, and go into orbit or land. Every step of the way is tested and retested. Having a failure of a space probe wastes hundreds of millions of dollars and years of the scientists’ and engineers’ lives. Probes have failed for minor reasons, including failing to convert English units into metric units or the failure of a single explosive bolt to fire.

JPL as Makerspace

JPL can be considered as the ultimate makerspace; all of the labs and shops at JPL have the overarching purpose of designing and building space probes and their instruments. Every project is unique, all results are innovations. As I have been told by JPL engineers, if it were easy or routine to make, they would have it done somewhere else. New technologies are tested all of the time, such as unfoldable solar sails, inflatable tires and habitats, probes with quantum level instruments and micro-thrusters that will fit inside a shoebox. Every building at the lab holds surprises. In one lab a cryogenic torpedo probe sits on a table. It has been designed and tested to melt its way down through layers of ice, sampling for signs of life along the way and sending data back through a wire tether to a lander. It may be used on a mission to land on Europa, a moon of Jupiter, and drill through the ice to test the liquid water ocean underneath. In another lab, a spider bot is being tested that can crawl down the cliffs of Valles Marineris on Mars. Rovers such as Curiosity, Perseverance, Spirit, and Opportunity are tested in an outdoor Mars Yard made to simulate the slopes, regolith, and rocks at a landing site. They are also tested inside at the In-Situ Instruments Lab. The Spaceflight Operations Facility receives data from probes in space through the Deep Space Network of radio antennas. The Multi-Mission Image Processing Lab takes that binary data and reassembles it into photos and 3D images.

Many different specialties are needed by JPL. Students with experience in digital imaging, data processing, engineering, 3D modeling and CAD, computer programming, planetary science, electronics, mechanics, and so on are in demand. JPL looks for many types of talented people, and the more experience they have with collaborative problem-solving, creativity, innovation, and making, the more attractive they will be. For example, Rob Manning was a drafting student in high school and college who was hired at JPL to help design space probe parts. His talent has been recognized, and he is now in charge of the Seven Minutes of Terror of Mars landers and rovers, the most critical phase of Entry, Descent, and Landing. A thousand things must happen at exactly the right moments for a probe to successfully land on Mars. That so many probes are successful and last well beyond their designated life spans (the Mars Odyssey probe has been in orbit 19 years) is testament to the quality of engineering and craftsmanship at JPL.

To identify talented students and encourage them toward STEM careers, JPL brings in high school and college interns each summer to work with project engineers. Many of these go on to permanent jobs at JPL. They have a very active Education and Public Outreach department headed by David Seidel, one of my favorite people on the planet and whom I have worked with to provide educator workshops. As a teacher visiting JPL, one is struck with the focus and single-minded purpose of the employees and their attitude of being able to bring about the impossible, literally doing what has never been done before. The culture of experimentation, questioning, collaboration, thinking outside the box, testing, revision, and engineering makes it one of the most exciting places to visit on the planet.

Emergent Themes:

In conclusion, my study of makerspaces has shown some common themes across all of the levels of makerspaces:

Training: There is a continuing need for training of both patrons and teachers/ directors/ employees. As new technologies and equipment are added to makerspaces, teachers find it difficult to take the time to learn and practice the new technology. Patrons need to be certified on new equipment and receive training on using design software. Some makerspaces solve this problem by having experienced students teach new students, or through formal classes or one-on-one instruction as time allows. Other spaces use videos to train patrons on equipment. Some makerspaces require formal certification before patrons can use equipment on their own.

Encouragement of Creativity: Although little evidence was found of formal teaching of creativity and innovation, all makerspaces encourage and support creativity either deliberately or indirectly. There is a major disconnect between the expectations of university level makerspaces and high school makerspaces; few high schools teach innovation or entrepreneurship, yet university makerspaces are set up to incubate new businesses and therefore expect students to already know these skills. Some programs have been created, such as entrepreneurship as a college major with courses designed to teach business acumen, funding, and marketing for start-up businesses, but more needs to be done especially at the high school level to train students to be innovative inventors and entrepreneurs.

Challenges: Funding for initial set-up and continued maintenance and sustainability is the most common challenge followed closely by space; most makerspaces are short on room for building, testing, and storing projects. Another common problem for makerspaces in schools is lack of time for completing projects; teachers usually underestimate the amount of time required to creatively complete a project.

Structure: Makerspaces can either be highly structured and teacher-centered or they can be more student-centered where students work on individually chosen projects. Once common theme was that the structure of school makerspaces changes during the school year; at the beginning, when training on tools and equipment is needed, the lessons are more structured. As students gain competency, they are better able to propose and create their own projects.

Support for Content Area Subjects: When makerspaces are inside an individual teacher’s classroom, they are used to support content standards and objectives. When they are in school libraries with dedicated teachers, the integration with specific subject areas becomes weaker and the makerspace directors often use their own curricula or lesson plans. Often only an occasional teacher will visit or have student use the space to create content related projects, which lessons the potential benefit of school makerspaces. There is a general lack of training for classroom teachers on how they can integrate making into their lessons.

Demographics: In some schools, makerspace usage is dominated by white male students, but in others there is a more balanced and equitable demographic. At the beginning of the school year in K-8 grades, the girls usually work with girls, but the groups will become more mixed by the end of the year. In some schools minority students are well-represented, in others more needs to be done to ensure full inclusion. Many makerspaces need to be redesigned to allow accessibility by people with disabilities. More girls and minority students should be engaged in making if we are to ensure an equitable balance of future engineers and innovators.

I am not through with this research yet; I hope to visit a number of my colleagues in middle and high schools and to visit univeristy makerspaces and other commercial makerspaces over the next few years to see how creativity, innovatin, inventing, and entrepreneurship all fit together in makerspaces.

Here is a summary diagram I created as part of my final report for the case study course:

References:

Caruso, B. (2019). Innovation instruction in the academic library: A new focus. Journal of Electronic Resources Librarianship, 31 (2), 88-99.

Halbinger, M. (2018). The role of makerspaces in supporting consumer innovation and diffusion: An empirical analysis. Research Policy, 47 (2018). 2028-2036.

Kye, H. (2020). Who is welcome here? A culturally responsive content analysis of makerspace websites. Journal of Pre-College Engineering Education Research, 10 (2), Article 1.

Lassonde Entrepreneur Institute, (2016). Welcome to the Lassonde Institute, retrieved from YouTube on

12/11/20 at: https://youtu.be/9C0DXJjiAi4.

McAllister, G. (2019). MakerSpace review – Orem Public Library, retrieved from YouTube on 12/8/20 at: https://youtu.be/pnmJgHbro3o.

Moorefield-Lang, H. (2015). When makerspaces go mobile: Case studies of transportable maker locations. Library Hi Tech, 33 (4). 462-471.

Rouse, R., Krummeck, K, and Uribe, O. (2020). Making the most of makerspaces: A three-pronged approach to integrating a makerspace into an elementary school. Science&Children, Feb. 2020, 31-35.

Sheridan, K. et al. (2014). Learning in the making: A comparative case study of three makerspaces. Harvard Educational Review, 84 (4), 505-531.

Slama, J. (2019). New makerspace creates welcoming school culture at Midvale Middle, The City Journal, Dec. 4, 2019.

Steele, K., Cakmak, M., and Blaser, B. (2018). Accessible making: Designing a makerspace for accessibility. International Journal of Designs for Learning, 9 (1), 114-121.

Wong, A. and Partridge, H. (2016). Making as learning: Makerspaces in universities. Australian Academic & Research Libraries, 47 (3), 143-159.

Zammarano, F. (2013). United Nations International School’s makerspace AKA Collaboratory. Maker Ed, retrieved 12/8/20 from:

https://makered.org/blog/united-nations-international-schools-makerspace-aka-colaboratory/